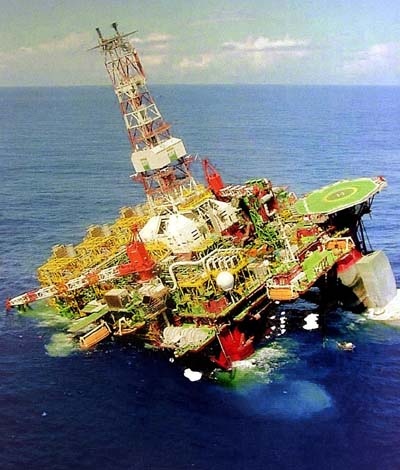

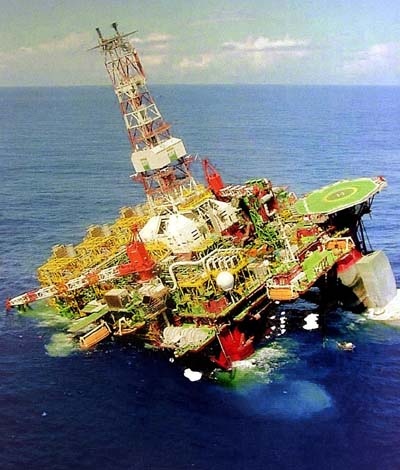

[h=1]Petrobras P-36 Sinking – The Biggest Oil Rig Sinking In the Oilfield Industry[/h]

Petrobras P-36 – This incident cost several million us dollars and it’s worthy to learn from it. One of the biggest global floating semi-submersible oil platforms Petrobras 36 (P-36), which was owned by Petrobras, an oil company in Brazil with its base of operations at Rio De Janeiro was destroyed after 20[SUP]th[/SUP] March 2011 when it sunk. The platform was then approximately valued at US$350 million. Its current value is US$466 million. Constructed and erected as a drilling rig in the year 1995, at the Fincantieri shipyard (Genoa, Italy), was owned by SocietàArmamentoNaviAppoggioS.p.A. The rig, which was a good 33,000 tonnes was transformed to the biggest global oil production platform by Davie Industry, Levis, Canada. P-36, which was functioning for Petrobras, about 130 kms off the coast of Brazil on the Roncador Oil Field daily generated approximately 84,000 barrels (13,400 m3) of crude oil. P-36 was substituted by a chartered vessel from SBM Offshore, FPSO-Brasil, which is in a lease contract with Petrobras since Dec 2002.

Formerly known as ‘Spirit of Columbus’, the P-36 was built and assembled in Italy for 10 years from 1984 to1994. The platform was crafted as a floating production unit and was based upon a conversion of the Friede & Goldman L-1020 Trendsetter-type semi-submersible. Later, it was revamped and re-crafted for Petrobras from around 1997 to 1999 and was functional in May 2000 in the Roncador Field off the Brazilian coast. It had the capacity to process daily about 180,000 bopd & 7.2 million cubic meters of gas. On May 2001, the P-36 began to generate daily approximately 84,000 barrels of oil & 1.3 million cubic meters, after which there were two blasts and following the explosions, it sank. Platform Loss

Formerly known as ‘Spirit of Columbus’, the P-36 was built and assembled in Italy for 10 years from 1984 to1994. The platform was crafted as a floating production unit and was based upon a conversion of the Friede & Goldman L-1020 Trendsetter-type semi-submersible. Later, it was revamped and re-crafted for Petrobras from around 1997 to 1999 and was functional in May 2000 in the Roncador Field off the Brazilian coast. It had the capacity to process daily about 180,000 bopd & 7.2 million cubic meters of gas. On May 2001, the P-36 began to generate daily approximately 84,000 barrels of oil & 1.3 million cubic meters, after which there were two blasts and following the explosions, it sank. Platform Loss

Petrobras P-36 – This incident cost several million us dollars and it’s worthy to learn from it. One of the biggest global floating semi-submersible oil platforms Petrobras 36 (P-36), which was owned by Petrobras, an oil company in Brazil with its base of operations at Rio De Janeiro was destroyed after 20[SUP]th[/SUP] March 2011 when it sunk. The platform was then approximately valued at US$350 million. Its current value is US$466 million. Constructed and erected as a drilling rig in the year 1995, at the Fincantieri shipyard (Genoa, Italy), was owned by SocietàArmamentoNaviAppoggioS.p.A. The rig, which was a good 33,000 tonnes was transformed to the biggest global oil production platform by Davie Industry, Levis, Canada. P-36, which was functioning for Petrobras, about 130 kms off the coast of Brazil on the Roncador Oil Field daily generated approximately 84,000 barrels (13,400 m3) of crude oil. P-36 was substituted by a chartered vessel from SBM Offshore, FPSO-Brasil, which is in a lease contract with Petrobras since Dec 2002.

On 14[SUP]th[/SUP] March 2001, almost around 10.30 p.m., drainage functions commenced on the portside EDT (emergency drain tank), one of the two 450 cubic meter tanks (one port, one starboard), and they were utilized for storing oil and water at the time of maintenance or any emergency. On 15[SUP]th[/SUP] March, at around 12.30 a.m., there was a blast in the starboard aft column possibly due to the mechanical cracking of the starboard EDT, which resulted in the discharge of water saturated with gas as well as oil into the aft starboard column and this resulted in the platform listing 2 degrees in no time. After this, there was another blast resulting in 10 casualties and one fire-fighting crew member being seriously injured. The consequent platform impairment and damage resulted in flooding in aft starboard column compartments & pontoon tanks, and this enabled passage of sea water via open sea chest valves. On the morning of 15[SUP]th[/SUP] March at around 8.15 a.m., the platform listed 16 degree, which immersed the chain lockers apertures on the main deck level and resulted in a progressive list casing loss of platform. Out of the 175 members, 138 were vacated by crane to boat on 15[SUP]th[/SUP] March from 1.44 a.m. to 4.20 a.m. and the rest of the people were vacated at around 6.00 a.m. on 15[SUP]th[/SUP] March by helicopter because the platform was unsteady and destabilized. For a couple of days after the catastrophe, a lot of efforts were directed towards alleviating and making the platform constant by infusing nitrogen in a vent line, which was close to the broken column, however due to unpleasant weather conditions, it was interrupted. Finally, at 11.40 a.m. on 20[SUP]th[/SUP] March, the platform overturned and then it sank in 1300 m of water, due to which salvaging the unit was a herculean task.

Conclusions When the platform submerged in the water, it had approximately 9500 bbls of oil on board, and about 2200 bbls of oil seeped out within just a day. Following this there were procedures and functions to dissolve the oil with chemicals and to obtain the oil back were undertaken in order to reduce the harmful impact of the incident. Det Norske Veritas framed and confirmed The Petrobras Inquiry into the P-36 sinking and it listed a detailed analysis of the series of episodes resulting in the P-36’s loss. Listed below were the possible reasons which triggered the catastrophe:

[*=left]Port EDT’s configuration to the Production Header rather than the Production Caisson, which enabled hydrocarbons making its way into the starboard EDT;

[*=left]The unanticipated oil and gas circulation along with water under pressure via entrance valve of starboard EDT, which triggered overpressure;

[*=left]The fissure of the starboard EDT, resulting in leakage of oil, water & gas that resulted into an overflow in the starboard column;

[*=left]Further overflow caused in the starboard column due to the fissure of the service sea water pipe in starboard column;

[*=left]Passage of gas to the elevated places of the starboard column through doors & ventilation hatches;

[*=left]A source of detonation which resulted in the blasting of the gas cloud;

[*=left]Two fire-fighting pumps which were instigated and started resulting in an overflow through the fissured sea water pipe;

[*=left]The breakdown of watertight dampers, causing water to attack all aft starboard pontoon rooms, along with the pump room, water injection room, propulsion room, & access tunnel;

[*=left]The water accessibility which resulted in dysfunctioning of the seawater pump, and the intake valves to sea-chest were not shut;

[*=left]There was more overflow and flooding through the open sea-chest valves which triggered a progressive platform list;

[*=left]The drowning of the chain locker pipes at the main deck level, resulting in down-flooding;

[*=left]Persisting gradual flooding of the starboard aft pontoon tanks & deck box compartments, till water finally gushed out and started overflowing in the central caisson resulting in the drowning of the platform

The primary causes were:

[*=left]Port EDT’s configuration to the Production Header instead of to the Production Caisson, which enabled hydrocarbons making its way into the starboard EDT;

[*=left]The holdback in activating the port EDT drainage pump, permitting the reverse flow of hydrocarbons for approximately 60 minutes;

[*=left]The breakdown of activators to shut ventilation dampers, which triggered the overflow of water into the starboard column & pontoon compartments;

[*=left]Two sea water pumps were still a work-in-progress with no contingency in case of a catastrophe;

[*=left]Insufficient planning for damage control and planning for working through a drastic emergency & stability control situations.

Ref: en.wikipedia.org/wiki/Petrobras_36, home.versatel.nl/the_sims/rig/p36.htm

by DrillingFormulas.Com on June 4, 2014

by DrillingFormulas.Com on June 4, 2014